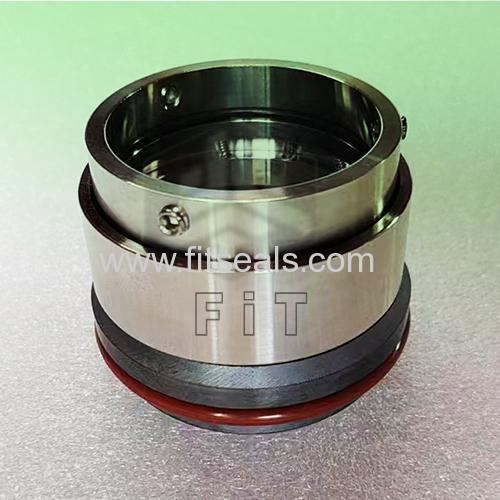

| Payment & Shipping Terms | Supply Capacity |

|---|

| Unit Price: | 55.0 USD | Production Capacity: | 300 SETS |

| Trade Term: | FOB | Packing: | cartron |

| Payment Terms: | T/T, WU, Money Gram | Delivery Date: | 25 days |

| Min. Order: | 3 Set/Sets | | |

| Means of Transport: | Air | | |

Seal to suit general applications. Also available in imperial sizes.

Alternative to:Burgmann HJ92N seal

Roplan 201 seal

Roten EHS seal

Hecker HN 435 seal

Ropac Propac 50 seal

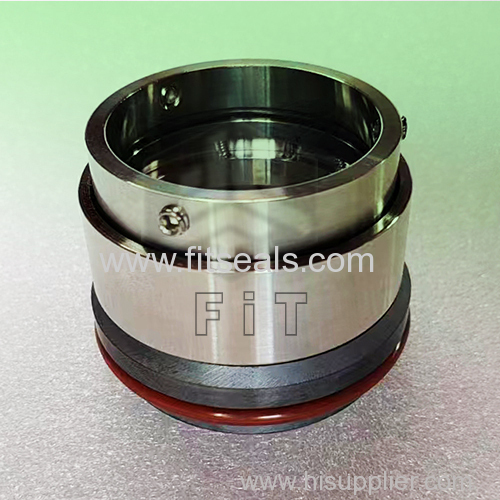

A mechanical seal is a very effective device. Every centrifugal pump must

accommodate a spinning shaft while mechanically maintaining fluid or gas contained

in the "wet end" of the pump. Mechanical seals consists primarily of a rotary

seal face with a driving mechanism which rotates at the same speed as the pump

shaft, a stationary seal face which mates with the rotary and is retained using a

gland or in some pump models an integral stuffing box cover, a tension assembly

(utillizing springs or a metal bellows) keeps the rotary face firmly positioned

against the stationary face preventing, excluding, and containing contamination and

leakage, both when the pump is not in operation and when the pump shaft is

rotating. Static sealing gaskets, orings or elastomeric bellows are strategically

located to complete the seal assembly.

We offer quality sealing and cost-effective mechanical seal designs that help keep

equipment running longer while reducing downtime. Through our comprehensive

selection we provide mechancial seals with short lead times and with a variety of

designs for use in many common and more challenging industry applications. When

selecting a mechanical seal, it is important to know what sort of design is needed,

and we have outlined a few of the more common elements below.

In-line Seals

In-line Seals simply refers to seals that are mounted to a shaft or sleeve but are

mounted independently as individual parts.

Single Spring Seals

Mechanical seal designs range from the work horse "single spring" mechanical seals,

to highly engineered double cartridge seals for extreme applications.

PTFE Seals

PTFE (polytetrafluoroethylene)or as most people know it Teflon ® , has a 0-14 ph

range it usually will hold up. Outside Seals

Outside Mechanical Seals can also be used in equipment with stuffing boxes which

will not accommodate inside seals, and they are easier to access for adjustment and

trouble-shooting.

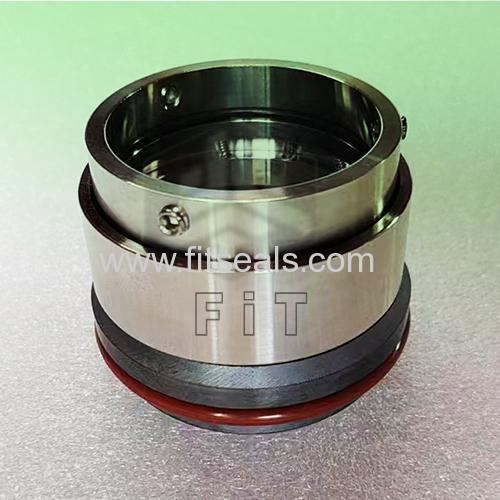

Single Cartridge

A Single Cartridge Seal is a pre-assembled package of seal components making

installation much easier with fewer points for potential installation errors to

occur.

Metal Bellows Seals

Metal Bellows Seals for pumps - The most common are AM350 and Hastelloy C. Usually

with Stainless Steel end fittings permits these mechanical seals to be used for

services beyond the range of mechanical seals with synthetic rubber sealing

members.

Tandem Cartridge

There are two basic double seal arrangements: Tandem Cartridge and face-to-face. A

double cartridge mechanical seal can be configured in either configuration.

Double Cartridge

Double Cartridge Seals - Tandem Cartridge Seal is a pre-assembled package of seal

components making installation much easier with fewer points for potential

installation errors to occur.

Seal Pots

Mechanical Seal pumbing plans you will know in some cases you will need a Seal Pot

to supply clean lubricating fluid to your seal.

Mixer and Agitator Seals

Mixers and Agitators Seals offer a unique problem for mechanical seals. Because

most mixers or agitators are mounted on top or on the side of a vessel the long

shaft being used to mix or agitate usually has an issue with run out.

Mechanical Seals - Face Materials

Mechanical Seals come in a wide range of designs however the most important factor

when determining how long a seal is going to last, is deciding on the right seal

face materials. The old adage "pay me now or pay me later" applies to seals. You

must consider the environment the seal will be exposed to. Abrasive environments

require seal faces that will hold up to the wear and tear of abrasive environments.

It makes little sense to save money on the seal only to have to spend more money to

replace the seal later. On the other hand if you are pumping very clean fluid that

has a lubricating quality such as machine oil or Ethylene Glycol, save your money

for better quality bearings.

Seal Faces:

Ceramic - Generally a 99.5% aluminum oxide offering excellent wear characteristics

due to it's hardness. It is chemically inert and can be applied to nearly any

product. Ceramic cannot however handle the thermal shocks that Ni-resist or 17-4

seats can. They will also shatter like a plate if dropped on concrete.

Silicon Carbide - Is a bluish-black material created by fusing silica and carbon. It

is in the same family as Ceramic (due to the Silica), but has much better

lubrication qualities and is harder. The most common is reaction-bonded silicon

carbide. In Chemical applications however, Alpha Sintered Silicon Carbide may be

recommended. Alpha Sintered Silicon carbide does however sacrifice the Pressure

Velocity ratios due to the lack of un-reacted free carbon. Either grade of SIC can

usually be re-lapped and polished to be reused.

Tungsten Carbide - A very versatile seal face like Silicon Carbide. It is very hard

like silicon carbide however it is very heavy to the touch, making it easy to

distinguish from silicon carbide. Ideal for high pressure applications due to a

high modulus of elasticity which helps prevent face distortion. Tungsten carbide

also can be re-lapped and polished to be re-used.

Ni-resist - Is a form of Stainless steel which has had nickel added to it to lower

the friction generated by the rotating face. it is an inexpensive seal face and

ideal for fresh water applications.

GFPTFE - Say that one ten times.... Glass Filled PTFE (most people just say Teflon

(R)). Gives the chemical resistance of PTFE however glass must be added to give the

face hardness and to prevent cold flow issues associated with PTFE.

Category: Other Pump Repair Kits