Mineral Oils, Synthetic Oils, Greases

Standard type for a broad range of applications in every sector of industry.

Rubber covered O.D. Assures sealing in the housing bore, even where there

is considerable surface roughness, thermal expansion or split housing.

Particularly suitable for sealing low viscosity and gaseous media.

Material:

NBR (Natural Rubber), Plain Steel insert, Spring Steel spring.

Max Temperature: -40°C/-40°F – 100°C/ 212°F

Max Surface Speed: 14 m/s

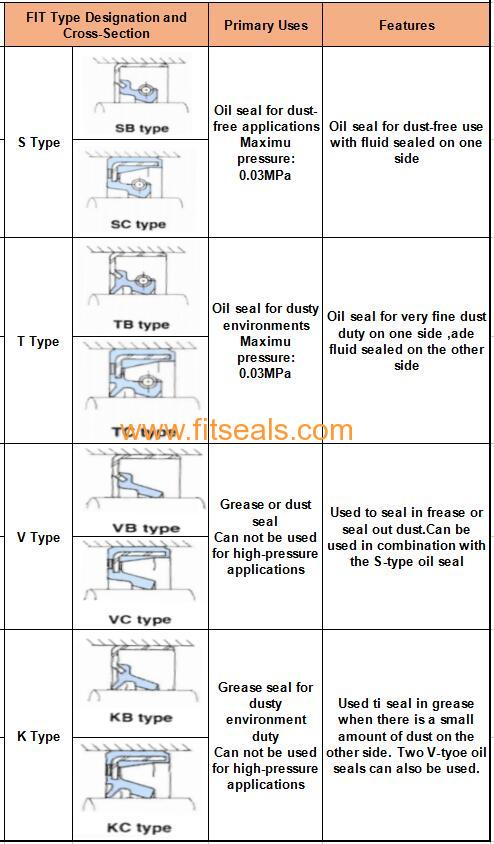

Oil Seals

Oil seals are available in numerous lip materials. Popular materials

include felt,

leather, urethane, nitrile, polyacrylate, ethylene-acrylic

or polyacrylic, silicone,

fluoro-elastomer, tetrafluoro-ethylene

propylene and PTFE. Use of one material

over another is application

specific, as materials will have different temperature

and speed ranges.

Oil seals also come in numerous constructions. Of particular

note is

the number of lips, with single and double lip being the most popular.

Many popular styles of oil seals will utilize a spring on the lip to

increase sealing

capabilities. Some oil seals have a coated metal casing

with a "rubber" lip while

other seals will be a uniform with the lip

material. Available in a wide array of sizes,

both inch and metric, most

oil seals are interchangeable between manufacturers.

Critical

dimensions on an oil seal include the inside diameter or bore (the OD of

the

shaft the seal rides on), the outside diameter (often called the

housing bore) and the

width. The ID and the OD are the most critical

dimensions, as it is the oil seal lip that

actually does the sealing. In

most applications, a replacement seal that is thinner in

width than the

original will work, as it will still fit into the grove provided.

Depending

on this groove dimension, on occasion, a wider replacement

seal will also work.

Oil seals should not be confused with U-Cups or

Packings that are designed to handle

higher pressure. A standard oil

seal is designed to handle low or no pressure.