mechanical shaft seals JOHN CRANE 609 metal bellow for high temperature use in oil pumps and chemical pumps that we sell is of high precision, good performance and competitive price

Rotary Welded METAL BELLOW SEALS,

Specifications

Stationary Ring(ceramic/SIC/TC

Rotary Ring(Carbon/SIC/TC)

Secondary Seal(NBR/EPDM/Viton/silica Gel)

Spring and metal parts

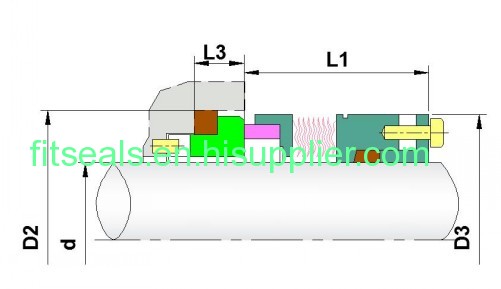

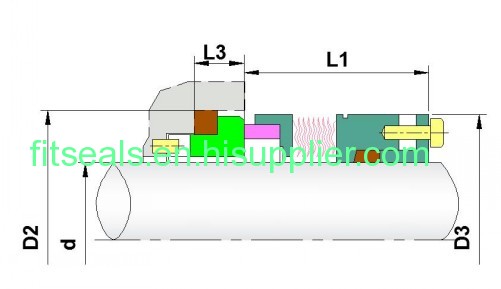

Type 609 is a high-temperature (to 425°C/800°F) rotating seal head assembly that incorporates all of the rugged features , but is intended for those demanding applications where a dependable, high-strength, rotating seal is preferred. A narrow cross-section design enables the type 609 to fit in the most popular pumps without expensive and time-consuming seal chamber modifications. This makes it the ideal seal for heat transfer, hydrocarbon and other applications that commonly use pumps with limited seal chamber clearances. Typical applications include hot hydrocarbons, aqueous solutions, aromatic fractionation products, crude oil fractionation products and heat transfer fluids.

Feature:

1. rotary bellows seal of hastelloy-c of low temperature rang

2. this mechanical seal rang make welded metal-bellows mechanical seal which is ultra thin .double decked and has double s to be there elastic component and have fine dynamic performace

3.this mechanical seal rang have simple and compact structure ,as well as easy installation,to leak few ,have high sealing reliablity

4.this mechanical seal rang have superior adhered and compensated nature,widdly used material ,strong adaptiveness to the envirnment and outstanding high temperature performance ,the stationnary design is better technical parameters.

Application:

Applicated in petrochemical ,oil refinging and cooling,the substances which use oil,organic dolvent,water and other weak corrosive solution to be there medium.

| /Size | D3 | L1 |

| 16 | 41.28 | 38.95 |

| 18 | 44.45 | 39.87 |

| 20 | 47.63 | 40.66 |

| 22 | 50.8 | 40.66 |

| 24 | 53.98 | 40.66 |

| 26 | 57.15 | 40.66 |

| 28 | 60.33 | 41.48 |

| 30 | 63.5 | 41.48 |

| 32 | 66.68 | 42.26 |

| 34 | 69.85 | 42.26 |

| 36 | 73.03 | 43.86 |

| 38 | 76.2 | 43.86 |

| 40 | 82.55 | 44.65 |

| 42 | 85.73 | 45.44 |

| 44 | 88.9 | 45.44 |

| 46 | 93.65 | 47.83 |

| 48 | 96.82 | 47.83 |

| 50 | 101.6 | 47.83 |

| 52 | 104.78 | 47.83 |

| 54 | 107.95 | 47.83 |

| 56 | 111.13 | 47.83 |

| 58 | 114.3 | 47.83 |

| 60 | 117.48 | 47.83 |

| 62 | 120.65 | 47.83 |

| 64 | 123.83 | 47.83 |

Metal bellows seals have many advantages over common pusher seals. The obvious advantages include:

- No dynamic o-ring eliminating the possiblity of hang-ups or shaft wear.

- Hydraulically balanced metal bellows allow the seal to handle more pressure without heat build up.

- Self Cleaning. Centrifugal force throws solids away from the seal face - Trim design allow fit into tight seal boxes

- Even face loading

- No Springs to clog

Most often metal bellows seals are thought of as High Temperature seals. But metal bellows seals are often effective in a wide range of other seal applications. The most common of these is chemical, general water pump applications. For many years an inexpensive form of metal bellows seals have been used very successfully in the waste water / sewage industry and in the agricultural fields pumping irrigation water. These seals were generally made of a formed bellows rather than a welded bellows. Welded bellows seals are much stronger and have superior flex and recovery characteristics which are more ideal to holding seal faces together but cost more to manufacture. Welded metal bellows seals are less prone to metal fatigue .

Because metal bellows seals only require one o-ring, and because that o-ring can be made with PTFE, metal bellows seals are and excellent solution on chemical applications where Kalrez, Chemrez,Viton, FKM, Buna, Aflas or EPDM are not compatible. Unlike an Type 9 seal the o-ring will not cause wear because it is not dynamic. Installation with a PTFE o-ring must be done with more attention paid to surface of the shaft condition, however PTFE encapsolated o-rings are also available in most sizes to aid in sealing irregular surfacing.