Burgmann MFL85N Metal Bellow Seal

FIT MFL85N is excellent replacement of burgmann original MFL85N seal, but with more competitive price.

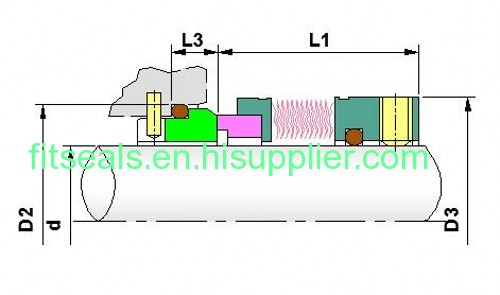

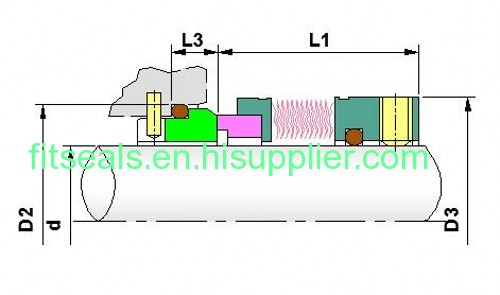

MFL85N is for unstepped shafts, single and balanced seal, with metal bellows rotating and independent of rotation.

MFL85N has many advantages ,like for extreme temperature ranges,No dynamically loaded O-Self cleaning

effect,Short installation length possible and Pumping screw for highly viscous media available

(dependent on direction of rotation).

Our factory can make and supply this type seal from shaft diameter 16mm to 100mm, with inch size from

0.63" to 4".

The operating range of MFL85N is as the following:

Externally pressurized: p1 = … 25 bar (363 PSI)

Internally pressurized: p1<120 °C (248 °F) 10 bar (145 PSI)

p1<220 °C (428 °F) 5 bar (72 PSI)

Temperature: t = -40 °C … +220 °C (-40 °F … 428) °F,

Stationary seat lock necessary.Sliding velocity: vg = 20 m/s (66 ft/s)

About the material of our MFL85N metal bellow seal, we can supply Carbon graphite antimony impregnated

(A)& Silicon carbide (Q12) Seal face and Silicon carbide (Q1) Seat. )Inconel® 718 hardened (M6),

| d1 | d3 | d6 | d7 | d8 | ds | l1K | l3 | l5 | l6 | l8 | l9 | l18 | l19 | b | s |

| 16 | 30 | 23 | 27 | 3 | 38 | 42.5*) | 32.5 | 1.5 | 4 | 17.5 | 10 | – | – | 1.6 | 9 |

| 18 | 32 | 27 | 33 | 3 | 39 | 42 | 30.5 | 2 | 5 | 14 | 11.5 | 15 | 7 | 1.6 | 10 |

| 20 | 33.5 | 29 | 35 | 3 | 41 | 42 | 30.5 | 2 | 5 | 14 | 11.5 | 15 | 7 | 1.6 | 10 |

| 22 | 36.5 | 31 | 37 | 3 | 44 | 37.5 | 30.5 | 2 | 5 | 14 | 11.5 | 15 | 7 | 1.6 | 10 |

| 24 | 39 | 33 | 39 | 3 | 47 | 40 | 28.5 | 2 | 5 | 19.5 | 11.5 | 15 | 7 | 1.6 | 8.2 |

| 25 | 39.6 | 34 | 40 | 3 | 48 | 40 | 28.5 | 2 | 5 | 19.5 | 11.5 | 15 | 7 | 1.6 | 8.5 |

| 28 | 42.8 | 37 | 43 | 3 | 51 | 42.5 | 31 | 2 | 5 | 19.5 | 11.5 | 15 | 7 | 1.6 | 9 |

| 30 | 45 | 39 | 45 | 3 | 53 | 42.5 | 31 | 2 | 5 | 19.5 | 11.5 | 15 | 7 | 1.6 | 8.5 |

| 32 | 46 | 42 | 48 | 3 | 55 | 42.5 | 31 | 2 | 5 | 19.5 | 11.5 | 15 | 7 | 1.6 | 9.2 |

| 33 | 48 | 42 | 48 | 3 | 56 | 42.5 | 31 | 2 | 5 | 19.5 | 11.5 | 15 | 7 | 1.6 | 9.2 |

| 35 | 49.2 | 44 | 50 | 3 | 58 | 42.5 | 31 | 2 | 5 | 19.5 | 11.5 | 15 | 7 | 1.6 | 9.5 |

| 38 | 52.3 | 49 | 56 | 4 | 61 | 45 | 31 | 2 | 6 | 22 | 14 | 16 | 8 | 1.6 | 9.2 |

| 40 | 55.5 | 51 | 58 | 4 | 64 | 45 | 31 | 2 | 6 | 22 | 14 | 16 | 8 | 1.6 | 9.2 |

| 43 | 57.5 | 54 | 61 | 4 | 67 | 45 | 31 | 2 | 6 | 22 | 14 | 16 | 8 | 1.6 | 9.2 |

| 45 | 58.7 | 56 | 63 | 4 | 69 | 45 | 31 | 2 | 6 | 22 | 14 | 16 | 8 | 1.6 | 9.5 |

| 48 | 61.9 | 59 | 66 | 4 | 72 | 45 | 31 | 2 | 6 | 22 | 14 | 16 | 8 | 1.6 | 9.2 |

| 50 | 65 | 62 | 70 | 4 | 74 | 47.5 | 32.5 | 2.5 | 6 | 23 | 15 | 17 | 9.5 | 1.6 | 10.5 |

| 53 | 68.2 | 65 | 73 | 4 | 77 | 47.5 | 32.5 | 2.5 | 6 | 23 | 15 | 17 | 9.5 | 1.6 | 10.5 |

| 55 | 70 | 67 | 75 | 4 | 80 | 47.5 | 32.5 | 2.5 | 6 | 23 | 15 | 17 | 9.5 | 1.6 | 10 |

| 58 | 71.7 | 70 | 78 | 4 | 83 | 52.5 | 37.5 | 2.5 | 6 | 23 | 15 | 18 | 10.5 | 3 | 14 |

| 60 | 74.6 | 72 | 80 | 4 | 85 | 52.5 | 37.5 | 2.5 | 6 | 23 | 15 | 18 | 10.5 | 3 | 14 |

| 63 | 79 | 75 | 83 | 4 | 88 | 52.5 | 37.5 | 2.5 | 6 | 23 | 15 | 18 | 10.5 | 3 | 14 |

| 65 | 84.1 | 77 | 85 | 4 | 95 | 52.5 | 37.5 | 2.5 | 6 | 23 | 15 | 18 | 10.5 | 3 | 14 |

| 68 | 87.3 | 81 | 90 | 4 | 96 | 52.5 | 34.5 | 2.5 | 7 | 26 | 18 | 18.5 | 11 | 1.6 | 10 |

| 70 | 87.3 | 83 | 92 | 4 | 96 | 60 | 42 | 2.5 | 7 | 26 | 18 | 19 | 11.5 | 3 | 17 |

| 75 | 95 | 88 | 97 | 4 | 104 | 60 | 42 | 2.5 | 7 | 26 | 18 | 19 | 11.5 | 3 | 16 |

| 80 | 98.4 | 95 | 105 | 4 | 109 | 60 | 41.8 | 3 | 7 | 26.2 | 18.2 | 19 | 11.5 | 3 | 16 |

| 85 | 104.7 | 100 | 110 | 4 | 114 | 60 | 41.8 | 3 | 7 | 26.2 | 18.2 | 19 | 11.5 | 3 | 16 |

| 90 | 111 | 105 | 115 | 4 | 119 | 65 | 46.8 | 3 | 7 | 26.2 | 18.2 | 20.5 | 13 | 3 | 21 |

| 95 | 114 | 110 | 120 | 4 | 124 | 65 | 47.8 | 3 | 7 | 25.2 | 17.2 | 20.5 | 13 | 3 | 21 |

| 100 | 117.4 | 115 | 125 | 4 | 129 | 65 | 47.8 | 3 | 7 | 25.2 | 17.2 | 20.5 | 13 | 3 | 20 |

Metal bellows seals have many advantages over common pusher seals. The obvious advantages include:

- No dynamic o-ring eliminating the possiblity of hang-ups or shaft wear.

- Hydraulically balanced metal bellows allow the seal to handle more pressure without heat build up.

- Self Cleaning. Centrifugal force throws solids away from the seal face - Trim design allow fit into tight seal boxes

- Even face loading

- No Springs to clog

Most often metal bellows seals are thought of as High Temperature seals. But metal bellows seals are often effective in a wide range of other seal applications. The most common of these is chemical, general water pump applications. For many years an inexpensive form of metal bellows seals have been used very successfully in the waste water / sewage industry and in the agricultural fields pumping irrigation water. These seals were generally made of a formed bellows rather than a welded bellows. Welded bellows seals are much stronger and have superior flex and recovery characteristics which are more ideal to holding seal faces together but cost more to manufacture. Welded metal bellows seals are less prone to metal fatigue .