Suit Hilge series pumps . It replace the vulcan type 128 seals.

Hilge Sanitary pumps rely on a variety of seals to perform pumping

applications with custom seals available for specific applications such

as brewery or beverage making applications.

Hilge replacement Pump Seals come in a variety of

custom and exotic materials depending upon your application

requirements. Materials such as Ceramics, Silicon Carbides, Tungsten

Carbides, High-Tensile Steel and Stainless Steel and are available for

immediate shipment from our facility.

Please provide us with your pump model number, serial number, pumping application and current seal type when ordering.

Mechanical Seals to suit Hilge Pumps. Machine specific seals found extensively in Food Process, Dairy and Brewery Industries.

used in Pump CRT, NK Series Pump

CLM-G,CLP-G Series Pump.

shaft size: 19mm,28mm,

REPLACEMENT

MECHANICAL SEALS FOR HILGE PUMPS,SPECIALIST IN PUMPS USED PRINCIPALLY

IN SANITARY PROCESSES OF BEVERAGE,FOOD AND PHARMACEUTICAL

INDUSTRIES.

The Pump Specific

group of seals are designed as alternatives to Original Equipment

Manufactures seals. They have therefore been designed for compatibility

with the equipment without the need for modifications to be made. The

largest range in the Pump Specific group is the product range which are

alternatives to the most common Flygt pumps.

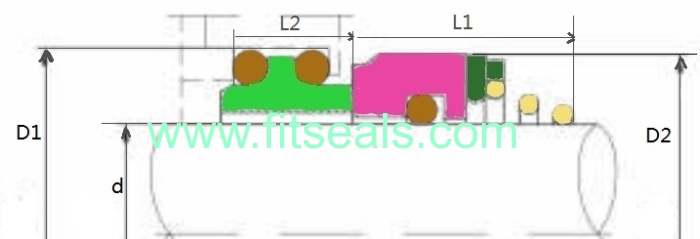

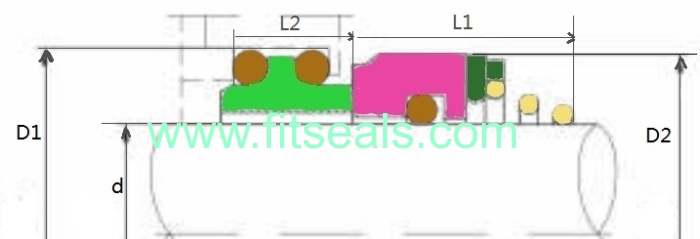

| Seal Size d | D2 | D1 | L1 | L2 |

| 19 | 31.0 | 35.0 | 20.0 | 15.0 |

| 28 | 40.0 | 41.3 | 24.5 | 15.5 |

The common centrifugal series includes; Hygiana®, Euro Hygia®,

Maxana®, Dura®, Sipla®, Contra® and Durietta®. However, the seal codes

are universal and you may identify your seal from the codes below.

Conversion to the direct replacement Vulcan balanced multiple-spring

design avoids the potential for premature single wave-spring failure.

We carry allweiler pump seals, EDUR pump seals, Speck Pump Seals,

Hilge pump seals, Seim pump seals and more in both standard cartridge

design and mechanical seals for both single and double set

installations.

Pump seals are available as either OEM or replacement from some of the best names in pump sealing today like John Crane, Smith and Loveless and more and are designed to work under the most adverse of conditions.

Our Pump Seals use the very best in Ceramics, Carbon,

Tungsten Carbides and other exotic materials for a quality fit and

operation in-between servicing and maintenance.