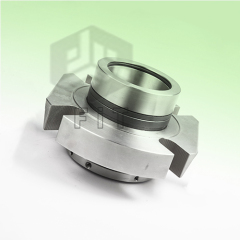

Replacement of Burgmann cartex Single cartridge mechanical seal.

Incorporates an elastomer O-ring as the secondary sealing member.

A common seal head/mating ring set, utilized throughout all versions, is reversible to allow rotating seat/mating ring or rotating seal head operation, and is interchangeable with metal bellows seal heads.

Reversible seal head.

Fits ANSI, ISO and DIN seal chambers.

Optimized primary ring design for greater reliability.

Non-clogging wave spring outside the product.

The high quality replaced burgmann cartex Single cartridge mechanical seal for pump that we sell is of high precision, good performance and competitive price.

This cartridge seal applies to heat oil pumps in all technical conditions of oil refining plants and chemical plants.

Our product includes Spring pusher seals,Rubber bellow mechanical seals,PTFE bellow mechanical seal,Metal Bellow Seals,Cartridge Seals,Mixer and Agitator seals,Dry Gas Seals.Besides, we can also supply spare parts with material silicon carbide, Tungsten carbide, Carbon ,Ceramic,rubber and stainless steel.

Our products are widely used in petroleum, chemistry, refinery, paper making, food,pharmaceutical, textile,power,marine.

Metal Cartridge mechanical seal

Features:

Self-align faces:Ensures that both the inboard and out board faces remain square,to the rotating shaft.

Springs loaded internal rotary centrifuges soilds away from the seal faces,resisting clogging from process fluids with high soilds content.

Process chemicals have diverse characteristics and one basic seal configuration fails to cover the board range of possible application.The need of exotic wetted alloys,various seal face combinations alternate O-Ring compounds,differential secondary fluid pressures,temperature control and barrier fluid containment systems are some of the design parameters encountered.

The FIT Cartex Cartridge seal equal to Burgmann cartex seal.

Balanced type caused the change of seal pressure is insignificant to that of working faces' pressure.

OperationalLimits: Combined Materials:

Temperature: 20℃~220℃ Stationary ring : Car/Sic

Pressure: 13 bar Rotary Seat: Sic/TC

Speed: 16m/s Metal Parts: SUS316

| /Size | d | D6 | D4 | D5 | L | L2 | L1 | W | M | G |

| (/Metric) | h7 |

| MIN | MAX |

|

|

|

|

|

|

|

| 25 | 25 | 43 | 44 | 51 | 105 | 68 | 25 | 25.5 | 62 | 12.5 | 1/4" |

| 28 | 28 | 46 | 47 | 52 | 105 | 68 | 25 | 25.5 | 62 | 12.5 | 1/4" |

| 30 | 30 | 48 | 49 | 56 | 105 | 68 | 25 | 25.5 | 65 | 12.5 | 1/4" |

| 32 | 32 | 50 | 51 | 57 | 110 | 68 | 25 | 25.5 | 67 | 12.5 | 1/4" |

| 33 | 33 | 50 | 51 | 57 | 110 | 68 | 25 | 25.5 | 67 | 12.5 | 1/4" |

| 35 | 35 | 53 | 54 | 62 | 115 | 68 | 25 | 25.5 | 70 | 12.5 | 1/4" |

| 38 | 38 | 56 | 57 | 66 | 125 | 68 | 25 | 25.5 | 75 | 12.5 | 1/4" |

| 40 | 40 | 58 | 59 | 68 | 125 | 68 | 25 | 25.5 | 75 | 14.7 | 3/8" |

| 42 | 42 | 61 | 62 | 70 | 133 | 68 | 25 | 25.5 | 80 | 14.7 | 3/8" |

| 43 | 43 | 61 | 62 | 71 | 133 | 68 | 25 | 25.5 | 80 | 14.7 | 3/8" |

| 45 | 45 | 63 | 64 | 73 | 141 | 68 | 25 | 25.5 | 81 | 14.7 | 3/8" |

| 48 | 48 | 66 | 67 | 75 | 141 | 68 | 25 | 25.5 | 84 | 14.7 | 3/8" |

| 50 | 50 | 68 | 69 | 78 | 150 | 68 | 25 | 25.5 | 87 | 14.7 | 3/8" |

| 53 | 53 | 72 | 73 | 87 | 150 | 68 | 25 | 25.5 | 97 | 17.5 | 3/8" |

| 55 | 55 | 74 | 75 | 84 | 150 | 68 | 25 | 25.5 | 98 | 17.5 | 3/8" |

| 60 | 60 | 78 | 79 | 91 | 157 | 68 | 25 | 25.5 | 102 | 17.5 | 3/8" |

| 65 | 65 | 83 | 85 | 99 | 165 | 68 | 25 | 25.5 | 109 | 17.5 | 3/8" |

| 70 | 70 | 93 | 95 | 108 | 180 | 68 | 25 | 25.5 | 126 | 17.5 | 3/8" |

| 75 | 75 | 100 | 102 | 118 | 190 | 85 | 27 | 25.5 | 129 | 17.5 | 3/8" |

| 80 | 80 | 106 | 108 | 124 | 195 | 85 | 27 | 25.5 | 135 | 17.5 | 3/8" |

| 85 | 85 | 109 | 111 | 128 | 200 | 85 | 27 | 25.5 | 139 | 20.5 | 3/8" |

| 90 | 90 | 116 | 118 | 135 | 205 | 85 | 27 | 25.5 | 145 | 20.5 | 3/8" |

| 95 | 95 | 119 | 121 | 138 | 210 | 85 | 27 | 25.5 | 148 | 20.5 | 3/8" |

| 100 | 100 | 125 | 127 | 144 | 218 | 85 | 27 | 25.5 | 154 | 20.5 | 3/8" |