Replacement AES T01 mechanical seals

Specifications:

Temperature: -20 till 200 °C

Pressure: 10 bar

Rotational velocity : 20 m/s

Rotating left: Yes

Rotating right : Yes

Tapered spring 'O' ring mounted DIN standard seal with G6 seat

Suitable for various duties by means of a choice of face materials

Alternative to:

Burgmann M32N/ M377N seal

Flowserve 38D seal

Sterling SM32N seal

8.DIN seal

Material :

Stationary faces : Ceramic, Silicon carbide, Stainless steel 316, Tungsten carbide,

Rotary faces : Carbon, Silicon carbide, Stainless steel 316, Tungsten carbide,

Elastomers : Aflas, EPDM, FEP Viton/Silicone, Kalrez, Nitrile, PTFE, Silicone, Viton,

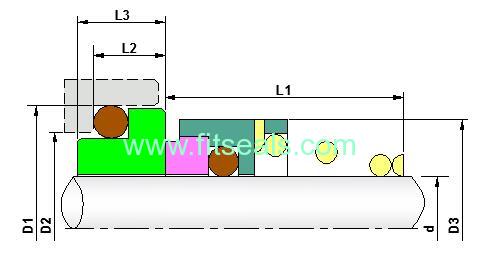

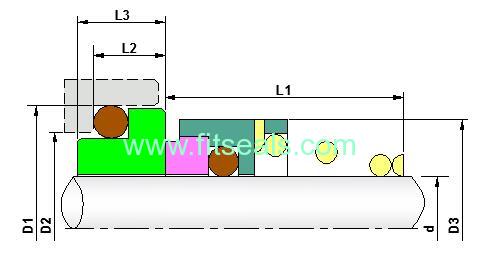

| Seal Size d | D1 | D2 | D3 | L1 | L2 | L3 |

| 10 | 21.0 | 17.0 | 19.0 | 15.5 | 6.6 | 7.5 |

| 12 | 23.0 | 19.0 | 21.0 | 15.5 | 5.6 | 7.5 |

| 14 | 25.0 | 21.0 | 23.0 | 15.5 | 5.6 | 7.5 |

| 16 | 27.0 | 23.0 | 26.0 | 17.5 | 6.6 | 7.5 |

| 18 | 33.0 | 27.0 | 29.0 | 18.5 | 7.5 | 8.5 |

| 20 | 35.0 | 29.0 | 31.0 | 20.0 | 7.5 | 8.5 |

| 22 | 37.0 | 31.0 | 33.0 | 21.5 | 7.5 | 8.5 |

| 25 | 40.0 | 34.0 | 36.0 | 24.5 | 7.5 | 8.5 |

| 28 | 43.0 | 37.0 | 40.0 | 24.5 | 7.5 | 8.5 |

| 30 | 45.0 | 39.0 | 43.0 | 24.5 | 7.5 | 8.5 |

| 32 | 48.0 | 42.0 | 46.0 | 28.0 | 7.5 | 8.5 |

| 35 | 50.0 | 44.0 | 49.0 | 28.0 | 7.5 | 8.5 |

| 38 | 56.0 | 49.0 | 53.0 | 31.0 | 9.0 | 10.0 |

| 40 | 58.0 | 51.0 | 56.0 | 34.0 | 9.0 | 10.0 |

| 43 | 61.0 | 54.0 | 59.0 | 35.0 | 9.0 | 101.0 |

| 45 | 63.0 | 56.0 | 61.0 | 36.5 | 9.0 | 10.0 |

| 48 | 66.0 | 59.0 | 64.0 | 42.0 | 9.0 | 10.0 |

| 50 | 70.0 | 62.0 | 66.0 | 43.0 | 9.5 | 10.5 |

| 55 | 75.0 | 67.0 | 71.0 | 47.0 | 11.0 | 12.0 |

| 58 | 78.0 | 70.0 | 76.0 | 50.0 | 11.0 | 12.0 |

| 60 | 80.0 | 72.0 | 78.0 | 51.0 | 11.0 | 12.0 |

| 65 | 85.0 | 77.0 | 84.0 | 52.0 | 11.0 | 12.0 |

| 68 | 90.0 | 81.0 | 88.0 | 53.0 | 11.3 | 12.5 |

| 70 | 92.0 | 83.0 | 90.0 | 54.0 | 11.3 | 12.5 |

| 75 | 97.0 | 88.0 | 98.0 | 55.0 | 11.3 | 13.0 |

| 80 | 105.0 | 95.0 | 100.0 | 58.0 | 12.0 | 15.0 |

For more information, quick quotations, expert consultation and responsive customer service

call us at or send us a quote.

This mechanical seal, for industrial pump, with advanced designer & manufacturer of mechanical seal, the range involves in: industrial pump mechanical seal, mixer and agitator seal, cartridge seal, metal bellows seal, auto cooling pump seal and auto air-condition compressor lip seal. Our products can replace the mechanical seals and be widely used in petroleum, chemistry, refinery, paper making, pharmacy, power and auto industry.

We take pride in our ability to help customers improve reliability, make a positive environmental impact and reduce operating expenses. One of our key strengths is our unmatched ability to deliver engineered seal product orders within 72 hours of a customer's request. Our worldwide, industry-leading Rotating Equipment Specialist program educates our engineers through hands-on and theory-based training courses, ensuring that our customers will receive outstanding service each and every time they do business with us.