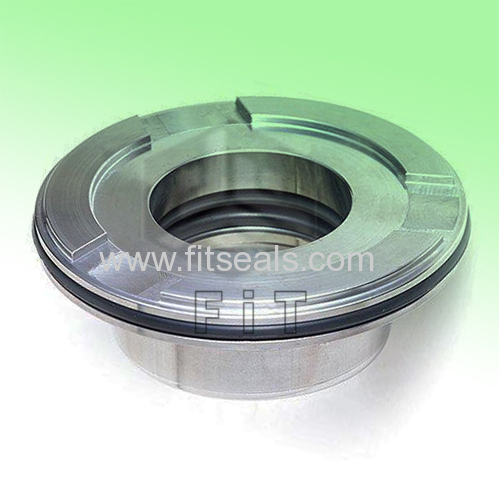

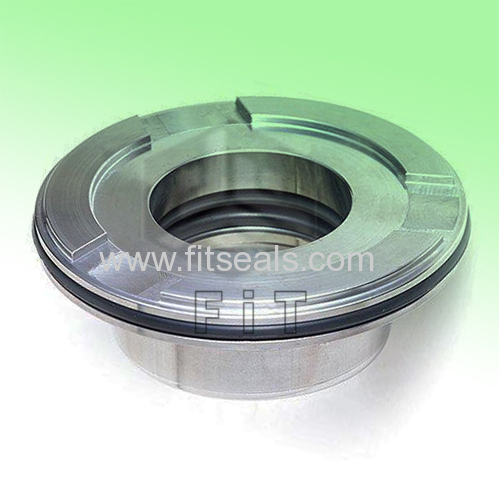

Blackmer pump shaft seal Blackmer brand pump cartridge seal 45mm seal

Our blackmer shaft 45mm pump seal is same design as original seal,with SS316/CARBON/VITON/SS316 material.

A mechanical seal is a very effective device. Every centrifugal pump must

accommodate a spinning shaft while mechanically maintaining fluid or gas contained

in the "wet end" of the pump. Mechanical seals consists primarily of a rotary

seal face with a driving mechanism which rotates at the same speed as the pump

shaft, a stationary seal face which mates with the rotary and is retained using a

gland or in some pump models an integral stuffing box cover, a tension assembly

(utillizing springs or a metal bellows) keeps the rotary face firmly positioned

against the stationary face preventing, excluding, and containing contamination and

leakage, both when the pump is not in operation and when the pump shaft is

rotating. Static sealing gaskets, orings or elastomeric bellows are strategically

located to complete the seal assembly.

We offer quality sealing and cost-effective mechanical seal designs that help keep

equipment running longer while reducing downtime. Through our comprehensive

selection we provide mechancial seals with short lead times and with a variety of

designs for use in many common and more challenging industry applications. When

selecting a mechanical seal, it is important to know what sort of design is needed,

and we have outlined a few of the more common elements below.

In-line Seals

In-line Seals simply refers to seals that are mounted to a shaft or sleeve but are

mounted independently as individual parts.

Single Spring Seals

Mechanical seal designs range from the work horse "single spring" mechanical seals,

to highly engineered double cartridge seals for extreme applications.

PTFE Seals

PTFE (polytetrafluoroethylene)or as most people know it Teflon ® , has a 0-14 ph

range it usually will hold up. Outside Seals

Outside Mechanical Seals can also be used in equipment with stuffing boxes which

will not accommodate inside seals, and they are easier to access for adjustment and

trouble-shooting.

A

A mechanical seal is a very effective device. Every centrifugal pump must

accommodate a spinning shaft while mechanically maintaining fluid or gas contained

in the "wet end" of the pump. Mechanical seals consists primarily of a rotary

seal face with a driving mechanism which rotates at the same speed as the pump

shaft, a stationary seal face which mates with the rotary and is retained using a

gland or in some pump models an integral stuffing box cover, a tension assembly

(utillizing springs or a metal bellows) keeps the rotary face firmly positioned

against the stationary face preventing, excluding, and containing contamination and

leakage, both when the pump is not in operation and when the pump shaft is

rotating. Static sealing gaskets, orings or elastomeric bellows are strategically

located to complete the seal assembly.

We also have seals for other pumps:

1. Waukesha®, mechanical seals for pumps, designed for all types of industries: food, beverage, personal care, lapel, etc.

WK-T-30

WK-T-40

WK-T-50

WK-T-60

2.

Mechanical seals for Wilo® pumps. These pumps are in use in the whole

world for yeating, air conditioning, supply of water and treatment of

waste waters. Available in two models of mechanical seals in different

shaft diameters.

3.Special designs for Tuchenhagen® pumps. Models used in the food industry specially in the dairy and juice processing.

TN-HG-25

TN-HG-30

4. Special mechanical seal for Suntec® pump, specialist in pumping liquid fuel.

SNT-A-25

5.Mechanical

seals for Someflu® pumps, made of specific materials to work with clean

or dirty products but chemically corrosives.

6.Mechanical seals for Sedical hot heating pumps, domestic water supply, and industrial pumps.

SD-A-12

SD-A-18

SD-A-32

7.

Mechanical seals for Salmson® pumps, specialists in pumping systems for

heating circuits and water supply in the industrial sector of waste

waters.

SM-AC-18

SM-AC-28

SM-AC-38

8. Special designs of mechanical seals for Pumpex pumps, materials suitable for contact with wastewater.

9. Marelli® mechanical seals for pumps used in centrifuge pumps for various applications: pumping clean water, sewage, etc.

10.

Mechanical seals compatible with different models of Lowara pumps.

Different types in various diameters and combinations of materials:

graphite-aluminium oxide, silicon carbide-silicon carbide, combined with

different types of elastomers: NBR, FKM and EPDM.

11. Mechanical seals for KSB® pumps, specialist in process pumping systems and heating pumps among others.

12. Mechanical seals for Johnson® pumps with a wave spring design suitable for this type of lobular pumps.

13.

Mechanical seals for Jabsco® pumps used in marine industry as drainage

pumps, engine cooling and industrial pumps for the transfer of

chemicals, aseptic applications, etc.

14.

Mechanical seals for Hilge® pumps, specialist in pumps used principally

in sanitary processes of beverage, food and pharmaceutical industries.

15.

Mechanical seals compatible for Hidrostal® pumps. Possibility of

supplying these special designs for different shaft diameters in inches.

16.Mechanical seals for available Herborner® pumps suitable for the pumping system of wastewater

HB-A-24

HB-A-28

HB-A-38

17.

Different models of mechanicals seals for a wide variety of Grudfos®

pumps, among them: CR(N), NB, NK, CLM, LP, TP, etc. Available in diverse

combinations of materials and different diameters: 12, 16, 22, 28, 33,

etc. Also mechanical seals for Sarlin®. Division of waster pumps.

Available in various materials: silicon-graphite carbide, silicon

carbide-silicon carbide; combined with EPDM and FKM elastomers.

18.

Mechanical seals are available for different references Gorman-Rupp®

pumps. Special models for the transfer of clean water, sewage, oil

industry, agriculture and others.

GRN-38'1

19.

Mechanical seals for Fristam pumps. Wide range of models and materials

in the most standard diameters: 22,30 and 35 mm. Different assembly

possibilities for the most well-known pump models: FP, FL and FT.

20.

Broad range of mechanical seals compatible with Flygt® and Grindex®

waste water pumps. These mechanical seals are characterized by their

easy and fast installation, without having to make any modification to

the pump. Manufactured in stainless steel and in solid tungsten carbide.

Special tools are not necessary for their installation.

21.

Mechanical seals for EMU® pumps. They get two static faces and one

rotating face. We can supply the complete seal or spare faces.

22.

Different designs of mechanical seals for Ebara® pumps, single and

double seals in combinations carbide-silicon carbide and

graphite-aluminium oxide.

23.

Mechanical seals for all types of Calpeda® pumps: centrifugal pumps,

multistage, submersible. Different models of mechanical seals in a wide

range of materials.

24.

Mechanical seals compatible for APV® pumps, among them: ZMA, ZMB, ZMD,

ZMS, ZMH, ZMK. Rosista® and Pasilac®, W and W+. Some designs with wave

spring like the special seals for APV Howard® pumps and Crepaco Clean

Line®. All of them have been manufactured in materials suitable for

working with fluids such as juices, milk and drinks in general.

25. Allweiler, Simple design of mechanical seals simple but with special measures for this type of pump.

26.

Different models of mechanical seals compatible forpumps series CM, FM,

MR, LKH,GM and ALC. Also the models for the range of lobular SSP and SR

pumps. Mechanical seals in different combination of materials tungsten

carbide, silicon carbide, graphite; combined with different types of

elastomers: NBR, EPDM and FKM.

27.

Mechanical seals for ABS® submergible pumps specific wastewater

treatment. Different models of mechanical seal available: oil chamber

mechanical seal and water mechanical seal.